1999 Mazda Capella

1. What are the 4 gas readings with the analyser probe sensing normal air?

Results indicate the air is quite clean, and can only read a high rate of oxygen, and a small amount of H.C.

2. What are the 4 gas readings while the engine is idling cold?

As the engine is cold, it needs to run a rich mixture because the air in the engine is still cold and dense, but because the fuel ratio is very high, the partially burnt fuel is emitted as Hydrocarbons (HC).

Because of the lack of O2, the Hydrogen is easier burnt off from the HC, and the Carbon particles which remain need to bond to something, so it bonds to the Oxygen particles, which cause a higher percentage of carbon monoxide (CO) which is deadly if someone inhales approximately 0.03% CO.

CO2 percentage is up too, since some of the O2 and C particles have bonded with each other. CO2 is more desirable than HC or CO since it isn't as harmful.

3. What are the gas readings when the engine has warmed up?

When the engine has warmed up a bit, the CO levels have come down a lot, also HC & CO2 levels are down, and O2 is up. This is because the engine is running a leaner fuel mixture now because the air is no longer dense or cold. Because the engine has appropriate heat, not as much fuel is required, so total emissions have decreased.

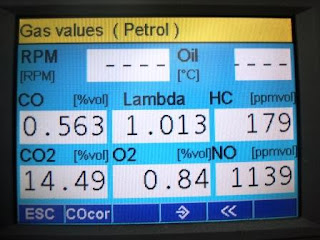

4. What are the gas readings when the engine is warm, and run at 2500 RPM?

When doing this, the vehicle is running more richer than at warm idle.

The HC is still low, thats because there isnt so much unburned fuel, but CO & CO2 are high while the O2 reading is extremely low. That is because the engine is running at a moderately rich mixture.

5. At idle run the mixture rich with extra propane, LPG or carburettor cleaner, and record the gas readings.

By spraying carb cleaner into the air filter it enriched the air/fuel mixture.

The HC is down surprisingly, but it means that its being burnt efficiently.

CO is down also because there isnt so much HC being burnt improperly, and the catalytic

converter is doing its job correctly.

CO2 & O2 is still up a bit. This is good, it shows that the engine is running efficiently when running a rich mixture.

6. At idle create a lean condition with an air leak or vacuum leak. Record the gas readings.

As the air leak was created, the HC went high. This was caused to the air/fuel ratio being incorrect. There wasnt enough air to help the fuel burn more efficiently.

The CO2 went down slightly, and the O2 went slightly higher along with the CO. The CO is becoming higher because, the engine is running more leaner.

7. Accelerate the engine, by blipping the throttle a few times and watch how the gas readings change.

CO: 4.253%

HC: 110ppm

CO2: 5.72%

O2: 8.17%

CO becomes extremely high yet the HC drops. This indicates that the engine is running a very rich mixture, yet is combusting properly. Cat converter is also working properly.

8. Disconnect one spark plug wire, ground it with a jumper wire, then record the gas readings as the engine idles.

HC is extremely high. This is because there is a misfire, and the air/fuel ratio isnt combusting properly. This misfire also causes the CO to increase because the Hydrogen particles are being burnt off leaving a volatile Carbon particle to bond to an oxygen particle becoming CO.

The O2 is also now higher than the CO2 reading, because the amount of unburned fuel is increasing the need for O2.

When the CO2 is high, and the rest are lower, it generally means that the engine is running efficiently. So since the CO2 is low here, it proves there is something wrong in the engine; the spark plug misfire.

9. disconnect the injector harness connector from one injector, and record the gas readings as the engine idles.

Disconnecting the injector harness made the HC, CO and O2 moderately increase.

and CO2 decrease. This is because the engine is running rich, and there is a misfire.

10. At idle, measure the gas readings while air conditioning is on and rocking the steering wheel.

All readings are acceptable, and not much wrong with it apart from a decrease in O2 and an increase in CO. This is because the air con is causing the engine to run slightly richer.

The extra emissions caused by having the air con running and rocking the steering wheel is minimal.

1. At this point, the sensor is directly in between the crank teeth giving a neutral magnetic force, and thus reading 0v.

1. At this point, the sensor is directly in between the crank teeth giving a neutral magnetic force, and thus reading 0v. The blue line indicates what the readings may be if the sensor was faulty.

The blue line indicates what the readings may be if the sensor was faulty. 1. At this point, the sensor is directly in between the cam teeth giving a neutral magnetic force, and thus reading 0v.

1. At this point, the sensor is directly in between the cam teeth giving a neutral magnetic force, and thus reading 0v. a) Engine is idling. There is more vacuum so less voltage present. 1.8v.

a) Engine is idling. There is more vacuum so less voltage present. 1.8v. 1. At 0.00v, the acceleration begins and voltage rises.

1. At 0.00v, the acceleration begins and voltage rises.

.JPG)

.JPG)

.JPG)

.JPG)